Installation Instruction Wall Panels

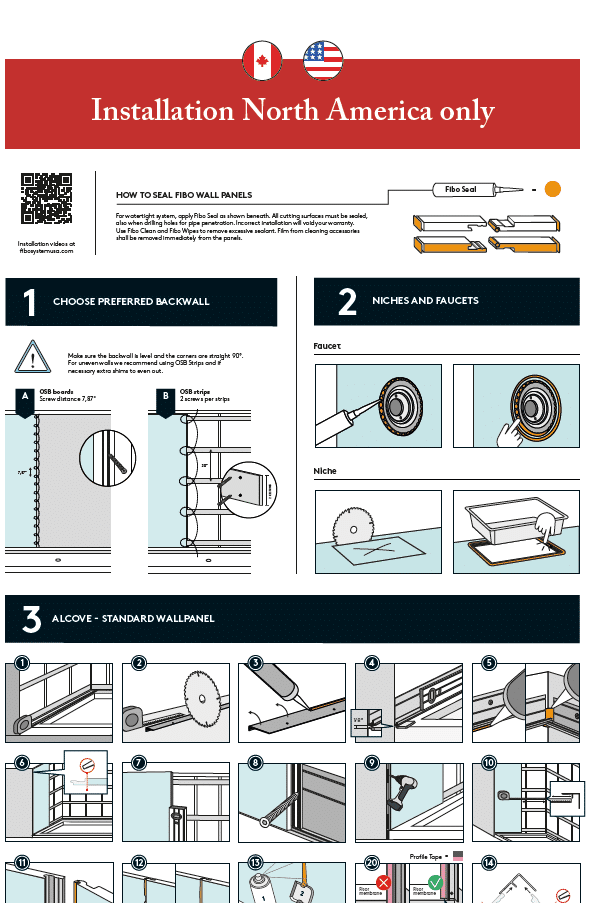

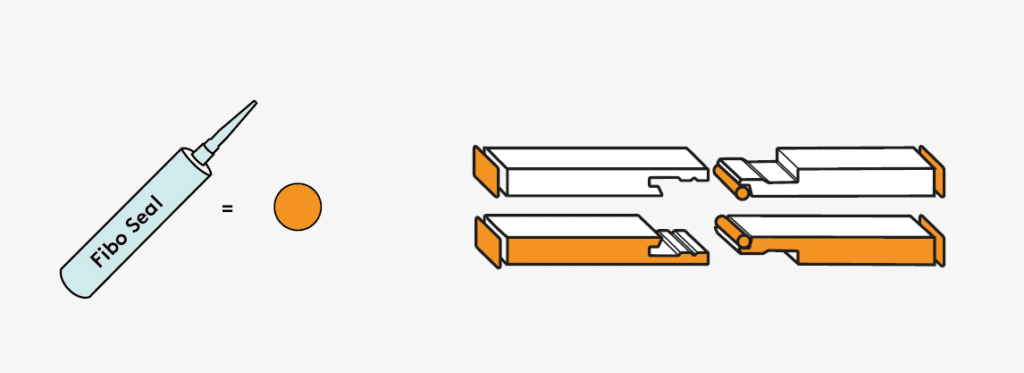

Fibo wall systems are made with different product components that create a simple and complete solution from start to finish. The wall system is installed by first setting up profiles like a base profile and internal corner profiles. This will form the framework of the wall system. The panels are installed, and all joints and cut surfaces are sealed with Fibo Seal. You finish the installation by using L-shaped finishing profiles. Accessories for support during the installation session are also available to make it easier and secure a good result.

Preparations before installing Fibo wall systems

Panel handling before opening packages

1. Keep panels in the plastic packaging and in a dry environment. Lay flat when storing and transporting.

2. Fibo wall panels must be kept at room temperature for at least 72 hours prior to installation.

3. Remove the plastic wrapping and check for any surface damage.

4. Carefully move the panels, avoiding any scapes and scratches along the edges and surfaces.

Preparing the floor and back wall

The floor must be prepared before installing panels on the wall. The floor membrane must extend at least 6-inches up from the floor. Fibo panels can be installed on existing walls or directly on the wall studs. The studs should be 24-inches apart and 32-inches tall. When installing on wall studs, the center distance must be 24-inches and the horizontal blocks/nail strokes must have a center distance of 32-inches. The wall must be reinforced where you hang a sink basin or other bathroom fixtures. When installing Fibo on existing walls, you can use one of the following three alternatives:

- Plywood board 0.5-0.6 inches

- 0.7-inch rough panel (mounted horizontally c/c 12-inches)

- 0.5-inch OSB klasse 3

When installing on concrete or steel studs, contact our customer service department.

Grouting and cleaning during installation

Click-lock, cut surfaces and profiles must be cleaned before grouting with Fibo Seal. We recommend using Fibo Seal on all plate joints and corner profiles.

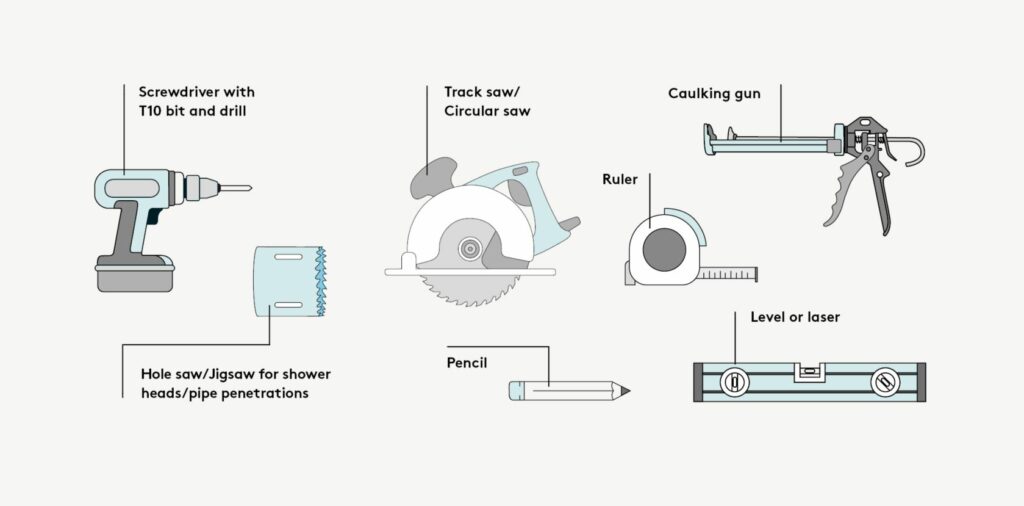

Tools you need

Wall Panel installation instruction

Our 100% waterproof Wall Panels can be installed on various back wall options as well as directly on to wooden or steel studs.<br>Underneath you will find downloadable PDF of our latest installation instructions and our Product & Installation Guide.

Find the correct accessories

Fibo installation accessories come from our own line of wall system completion products – and ensure both easy installation and a perfect result.

Frequently asked questions

The Product will not delaminate, stain, fade or crack during the Warranty period as a result of defects in materials and manufacture of the Product, when properly installed in accordance with Fibo’s installation instructions and cared for in accordance with Fibo’s instructions for Cleaning and Maintenance or Product Guide, more details in Technical Data

Please note where the temperature is above 80°C/176°F eg. behind some gas stoves and

cooktops, we recommend using a heat resistant decorative material(stainless steel is commonly

used) or tempered glass product to protect the panel and avoid heat possibly dulling the

panel. Please check with the manufacturer of gas appliance to determine required wall clearance

for gas appliance installation to ensure temperatures don’t exceed the level listed above where

Fibo Kitchen Board is installed. Freestanding Ranges with a rear vertical control panel/display do

not apply to this concern.

Fibo can be used in most rooms, but there are exceptions. Like swimming pools and saunas. On the other hand, Fibo is excellent for changing rooms, showers and other spaces adjacent to saunas and swimming pools.

Yes, Fibo is approved for all wet room zones, for example, in the bathroom shower. This is due to the membrane in the sealing layer. Our panels are excellent in all wet rooms, but also where extra-durable walls are needed, like in hallways, garages or laundry rooms. Fibo Kitchen Board is built the same way and also waterproof.

Many of our panel models are delivered in 10-foot heights. If the model you choose cannot be found in the desired height, we have a list you can use to add the wanted height to Fibo.

The most safe and versatile installation method is with the OSB strips. See how on this link.

If you plan to mount bathroom fittings, a washbasin, faucet, wall-mounted toilet or other bathroom furniture on the panel, you need to install, for example, a 0.5-inch thick sheet of plywood behind it. You can, of course, attach the decor to studs behind the wall.

Fibo Seal is specially developed for our panels and is ETAG 022 approved. Fibo Seal is also supplied in the same colors as the joints on the panels. Do not use silicone, only MS polymer sealant approved according to SINTEF TG 2289.

Use the Purchase calculator to find out what’s necessary for your installation. If you need more guidance please contact your supplier of Fibo panels, or Fibo directly at info@fibosystemusa.com.

For installation on masonry/concrete walls above ground, use the following solution: Make sure the concrete is dried out and has a maximum moisture level of 85% when mounting. The substrate must be level and provide good attachment possibilities for nails and screws where the panels meet. Remember, where you hang up washbasins or other heavy objects, there must be extra reinforcement.

Forget about the vapor barrier, primer, fix and joints. Fibo panels have an integrated vapor barrier and you can mount the panels directly on the wall framework.

Yes, Fibo can be glued onto old existing tiles. Ask a craftsman or a hardware store for the most suitable glue. You can view the complete installation guide at this link.

Yes, it is safe to glue Fibo onto drywall, however check the suppliers requirements for extra support before installing a seat, niche or grab bar.